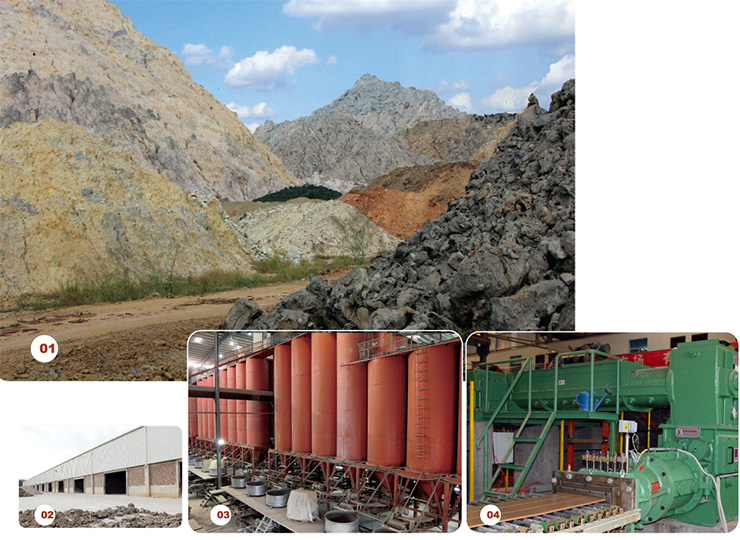

LOPO focuses on source and technology. From the quality control of raw materials to production, LOPO always makes sure all the details of each process are guaranteed and ensures that each piece of terracotta panels / terracotta tiles has great quality.

LOPO Terracotta Corporation has world-class production lines and equipment which is imported from Italy and locally produced by ourselves. The annual production capacity is about 4,500,000 square meters of Clay Tiles, 600,000 square meters of Cultured Stone and 1,500,000 square meters of Terracotta Facade Panels. Every indicator of energy consumption has reached a leading level.

Production line characteristics

– 80,000 square meters of open-air stockyards with a natural clay raw material stock of 300,000 tons;

– Reserves of 150000 tons indoor storage bin;

– Reserves of 12000 tons mud materials storage system;

** The large capacity reserve of raw materials ensure the stable quality of products;Orders with large quantities are available for quick delivery requirement;

– Advanced Italian molding equipment;

** Stable extrusion molding; prevents defective products, such as cracking inside, uneven thickness and so on;

– Dried slowly in a five –layer kiln at 80 meters highness;

** Enough time and space for the optimization of semi-finished panels; in addition, the large capacity of the green brick storage system ensures the stable operation of the main kiln;

-The longest roller kiln (260 meters) with 428 firing units;

** The longest roller kiln in China; guaranteed product quality;

– Automatic cutting and edge grinding machine;

** Reduce human errors; improve efficiency; ensure product consistency.

We are committed not only to the growth of our company, but also to our social and environmental responsibilities. We will devote our utmost efforts to harmonizing our mutual homes with green products.