rate of non-beam dry hanging terracotta curtain wall to 95%

How to improve the inspection pass rate of non-beam dry hanging terracotta curtain wall to 95%

rate of non-beam dry hanging terracotta curtain wall to 95% introduction:

How to improve the inspection pass rate of non-beam dry hanging terracotta curtain wall to 95%

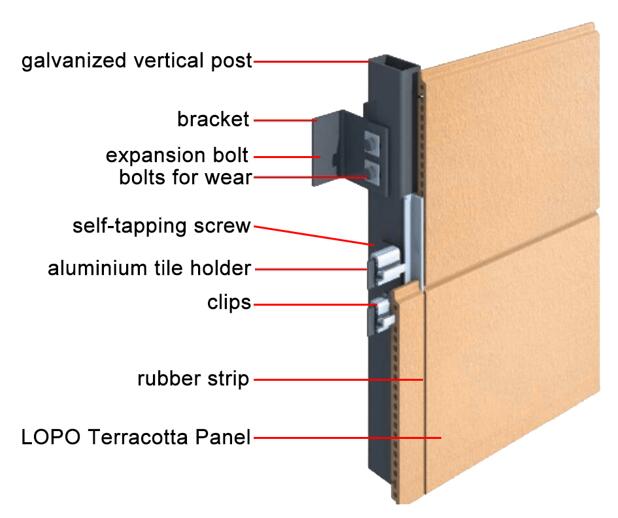

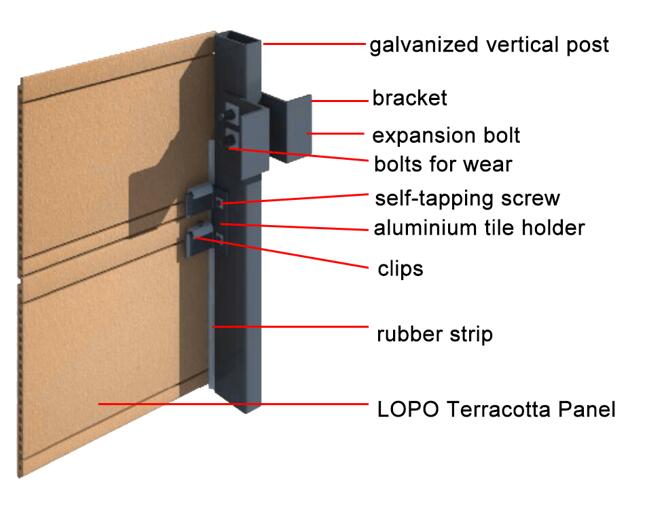

In the traditional terracotta panel installation structure, the construction unit mainly adopts the installation structure of the horizontal beam and the vertical post, but it requires more material cost and installation cost, and the structure is complicated. The beamless mounting method simplifies the structure and greatly reduces material and construction costs. Now we provide solutions based on some installation problems feedback from the construction site.

Problems that arise:

The failure rate of surface is uneven and the joint is not flat is 71.55%, 5077% for the connector is not qualified, and the terracotta panel installation unqualified rate is 30.77%.

Analyze the reasons:

The construction unit did not combine the design standards to carry out technical work. The materials quality entering the site were not strictly controlled, and no strict tests were carried out on the materials. No specific skills training for personnel. The welding of the bracket and the column is not accurate, which adversely affects the flatness of terracotta panel and the joint, and reduces the construction quality. The base wall is not flat and the measurement accuracy is not up to standard. The measuring instrument has not been verified, which affects the effect of the actual calibration.

Solution:

For the problem that the connector is not in a straight line, control the position of the built-in fitting, spot weld the connector and the column, and control the horizontal deviation of the connector from the top to the bottom with the pass line. After the laser theodolite meets 100% pass, perform full soldering.

The bracket and the post are not welded accurately. The construction personnel determines the bracket installation mark according to the installation position of the column, and pops the ink line installed on the column on the column. In the process of bracket welding, the construction unit should combine the construction site conditions, align the position of the bracket, control the verticality of the column and bracket, and then carry out the bracket and column welding and anti-rust treatment.

For the problem that the clip is not provided with a flexible connection, a circular spring piece is used as a springboard between the terracotta wall panel and the clip, and the plastic spacer serves as a flexible connection between the pendant and the bracket.