The Terracotta Cladding System(Terracotta Curtain Wall System) has become the first choices of exterior wall decoration for more and more upscale buildings.

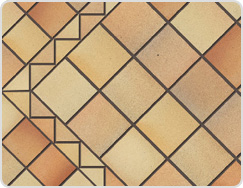

Terracotta cladding is made from 100% natural material, mainly composed of natural clay mixed with natural water, and with high temperature firing work. Combined with other facade system materials, such as glass, stone, steel etc., the terracotta wall cladding systems crate the fantastic facade wall designs. It is widely used for the exterior of the building as an alternate to exposed brick masonry, which is rugged and untidy. The terracotta facade cladding system can solve this problem perfectly. The terracotta surface can be either glazed and unglazed with a variety choice in colors.

Tags: TERRACOTTA PANELS, Rainscreen Cladding, Ceramic Cladding, Exterior Wall Cladding System

LOPO Terracotta Company is a professional Terracotta Cladding products manufacturer and supplier in China. We have three factories and multiple production lines with more than 20 years of terracotta industry experience.

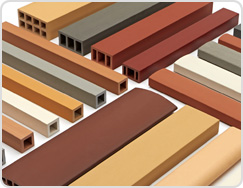

LOPO Terracotta Cladding System including these products:

Certificates of LOPO Terracotta Wall Cladding:

Advantages of Terracotta Cladding Panels

1. Colors

Stone: Single color which is unable to satisfied the requirements of the designer. What’s more, either marble or granite, the surface of it will fade and discoloration over time.

Metal Panel: It has poor durability and metal texture is too strong. It can not accomplished architect’s dream. It is also easy to deform and discolor ate in the windy and rainy weather.

Terracotta Panels: Terracotta Cladding Panels can visualize architect design and integrate architecture and art with its colorful and unique art.

2. Safety and shock resistance, acid and alkali resistance

Stone: It is natural items that has rich silicon oxide, aluminum oxide or calcium carbonate minerals, and all of them contain radioactive elements – chlorine.

Sheet Panel: Metal panels are feared of acid corrosion.

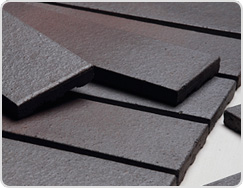

Terracotta Panels: The raw materials are natural clay, which do not contain any radioactive elements; after calcification in 1200 degrees Celsius kiln, a portion of mineral elements contained in the clay (aluminum oxide, silicon oxide or the like) has been completely oxidized.

3. Energy conservation

Stone: Non-renewable natural materials, and can not be recycled.

Metal Panels: Mainly use aluminum alloy, the resource of which has been almost mined up in the world. The thickness of the metal panels is limited. With its high thermal conductivity, it does not have any energy-saving effect.

Terracotta Panels: Clay is a renewable resource and can be recycled. The production determines its features of relative environmentally friendly, and low energy consumption. The hollow structure of Terracotta Cladding Panels and the appropriate insulation system play a very important role in energy conservation.

4. Installation

Stone: Installation of stone curtain wall is basically using back cut anchor bolt or grooved with clips to install.Both of these two methods will destroy the stone structure.

Metal Panel: the panel thickness is very thin. It is easily damaged and deformed by the external force, so it is with low safety performance.

Terracotta Panels Cladding: Installation problem has been considered when extrusion. Pre-made back groove is easy to mount. With up to 16-20 Mpa pressure strength, safety performance and seismic resistance is far superior to stone, metal plates and other materials.

Tags: Terracotta Curtain Wall, Terracotta Precast, Precast Terra Cotta Panels